Mass adoption of LED lighting has revolutionised energy efficiency, drastically cutting down our operational carbon footprint. Yet, a hidden challenge remains: the issue of lighting waste. In the UK, only a scant 8% of the overwhelming 40,000 tonnes of commercial lighting equipment is recycled each year. The issue arises from traditional business models that focus more on selling products and neglecting their end-of-life treatment. To tackle this, one must consider a light’s entire life cycle journey, from material usage through to disposal.

What is TM66?

TM66 stands for “Technical Memorandum 66: Creating a circular economy in the lighting industry”.

In October 2021, the Chartered Institution of Building Services Engineers’ (CIBSE’s) Society of Light and Lighting (SLL) launched the TM66 framework. This innovative framework provides a clear roadmap for designing and manufacturing sustainable lighting solutions. Crucially, TM66 champions a circular economy approach, minimising waste throughout a product’s lifecycle. Beyond simply offering guidance, TM66 features a transparent scoring system to assess the circularity of lighting products. By embracing these principles, the lighting industry can significantly reduce its environmental footprint and create more sustainable lighting solutions.

What is a Circular Economy?

A circular economy prioritises keeping resources in use for as long as possible. Therefore, it minimises waste through designing products for disassembly, remanufacture, and using recycled materials. This approach significantly reduces environmental impact across a product’s entire life cycle.

CEAM-Make: Assessing a products circularity

TM66 goes beyond just promoting circular economy principles; it provides a powerful tool to assess a lighting product’s circularity. This tool, the Circular Economy Assessment Method for Manufacturing (CEAM-Make), meticulously examines a product’s entire lifecycle through a series of 72 targeted questions.

CEAM-Make delves into four key areas:

- Product Design: Does the product prioritise longevity and ease of repair? Imagine a thoughtfully designed light fixture that can be easily disassembled for repairs or upgrades.

- Materials: This section explores the use of recycled materials. CEAM-Make favours products that incorporate recycled content over virgin resources, reducing environmental impact.

- Manufacturing: Here, CEAM-Make examines production techniques. The ideal scenario is efficient processes that minimise waste.

- Ecosystem: This facet looks at the manufacturer’s commitment to extending a product’s life. Ideally, the manufacturer offers repair or upgrade services, keeping the product in use for longer.

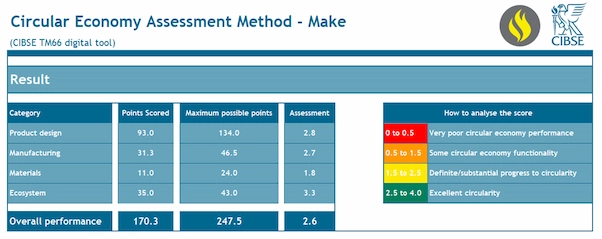

By addressing these crucial areas, CEAM-Make fosters a more active and comprehensive approach to evaluating the sustainability and circularity of lighting products. The following table showcases a real-world example of CEAM-Make in action, demonstrating how it breaks down the circularity score of a Panel LED.

Manufacturers can meticulously respond to these questions and secure a CEAM-Make rating for their product. Having a concise score presents a transparent and straightforward way to compare the circularity performance across various lighting products, marking a significant leap towards clearly communicating sustainability in the lighting industry.

How does TM66 impact the industry?

TM66 lays out a comprehensive framework that actively encourages the entire lighting industry to embrace circularity. With an approach emphasising designing products for easy disassembly and prolonged life, simultaneously guiding specifiers, manufacturers, contractors, and facility managers towards sustainable practices.

Moreover, embracing CEAM in lighting projects encourages a shift towards more responsible design, manufacturing processes, and consideration of the full product life cycle. The potential benefits are immense as we can conserve valuable resources whilst stimulating development in long dormant areas of British manufacturing.

How EGG Lighting uses TM66

We are passionate about ensuring transparency and quantifiability in circularity claims. In this vein, we are committed to empowering our customers with the information they need to make sustainable choices. Therefore, we plan to utilise the TM66 CEAM assessment method to comprehensively score all our products. This thorough evaluation will provide clear data on each product’s circularity performance, encompassing everything from design and materials to manufacturing and potential for remanufacture. By incorporating TM66 scores into our product information, we aim to simplify the selection process. This will ensure customers can confidently choose lighting solutions that align with their commitment to a sustainable future.