Embodied carbon in MEP (Mechanical, Electrical, and Plumbing) equipment is substantial but difficult to measure and report on.

Accurately gauging the embodied carbon emissions associated with MEP equipment is a complex task. To tackle this challenge, the Chartered Institution of Building Services Engineers (CIBSE) in the UK has developed TM65. This is a technical memorandum that outlines a methodology for calculating the embodied carbon of lighting products. TM65 is gaining recognition as a valuable tool for evaluating the environmental impact of lighting products.

What is Embodied Carbon?

Embodied carbon refers to the greenhouse gas emissions generated during the creation of a product. This encompasses its manufacturing, transportation, and installation phases. It’s crucial to consider embodied carbon when selecting new products. The industrial processes involved can significantly influence the overall environmental impact of a building or project.

How does TM65 work?

TM65 provides a framework for calculating the embodied carbon of lighting products. It considers the following factors:

- The materials used to manufacture the product

- The manufacturing process

- The transportation distance to point of use

- The installation process

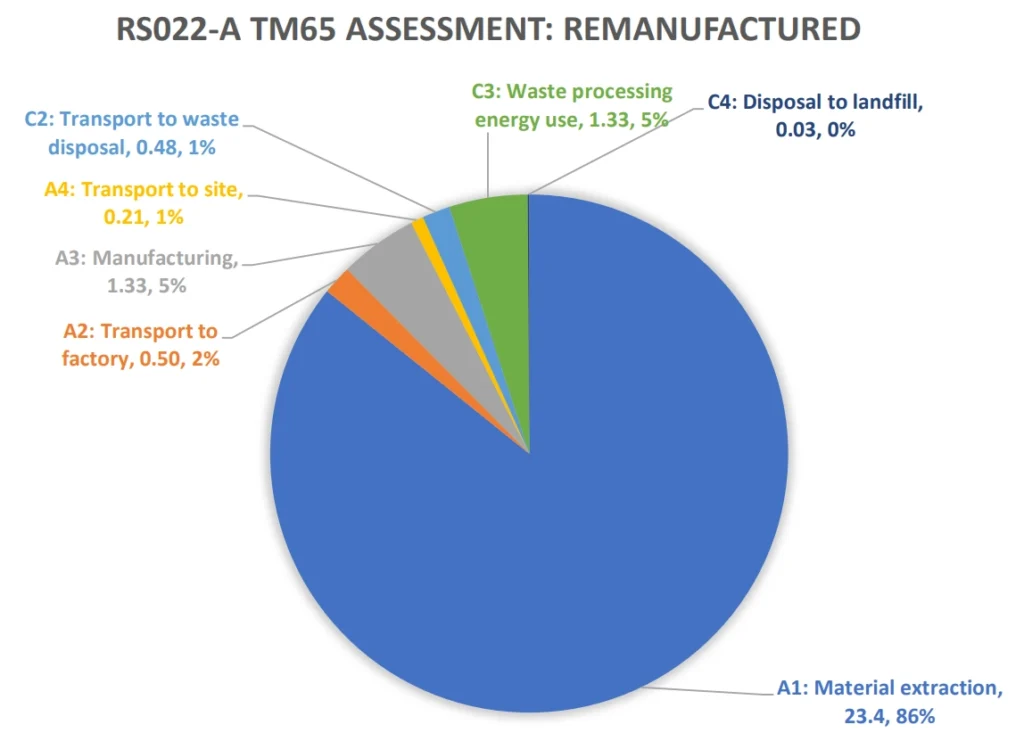

The pie chart below demonstrates a real case example of the embodied carbon calculation for a remanufactured LED Bulkhead.

Material extraction is an energy-intensive process that contributes the vast majority of the associated embodied carbon emissions. As a result, proper end-of-life treatment has become fundamental. Proper WEEE recycling and remanufacturing will play a crucial role, minimising waste and promoting circular economy principles.

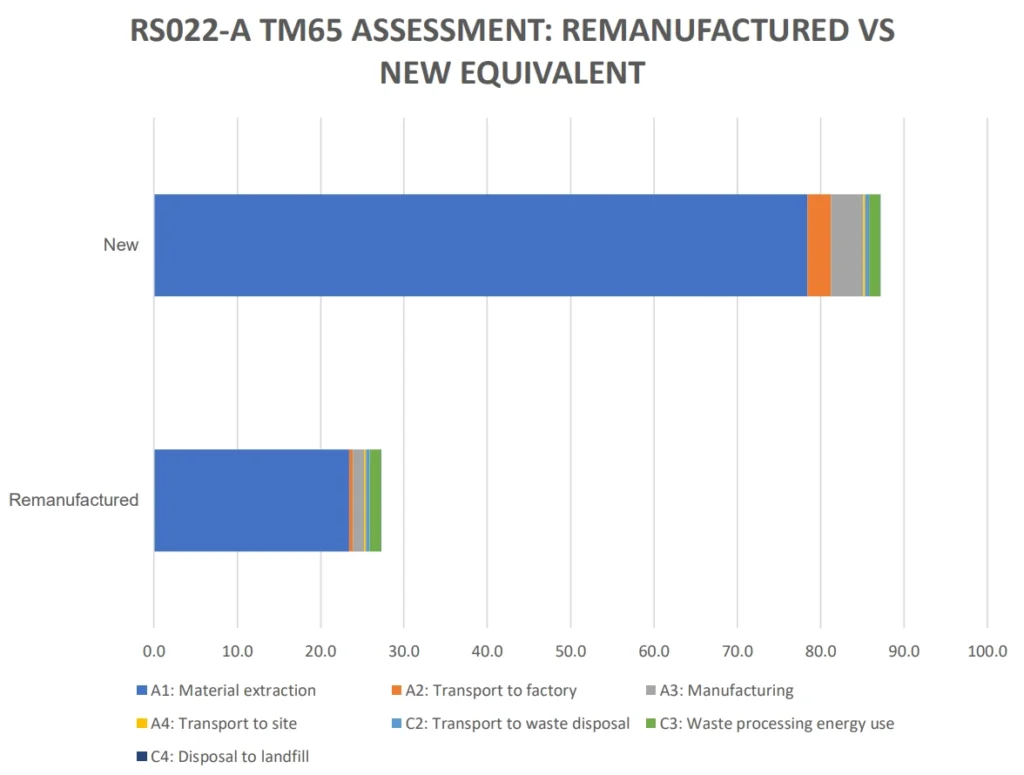

TM65 assigns a conclusive weight value (KgCO2e) to the embodied carbon of a lighting product. This provides valuable insights into its carbon intensity. The chart below is from the same example, illustrating a significant reduction in embodied carbon through the use of remanufacturing.

The comparison reveals a substantial difference in embodied carbon footprints between a newly manufactured light (around 90KgCO2e) and its remanufactured counterpart (under 30KgCO2e). This metric offers a consistent basis for evaluating the embodied carbon of various lighting products, empowering designers and engineers to make informed and environmentally conscious choices.

EPD's and considering the full life cycle of products

TM65 and Environmental Product declarations (EPD’s) both aim to assess the environmental impact of building products, but they differ in scope and methodology.

TM65 provides a standardised yet simplified approach to estimating embodied carbon. In contrast, EPDs are more detailed reports based on international standards and follow a comprehensive life cycle assessment (LCA) methodology, offering a more accurate environmental assessment.

Recent research indicates that TM65 tends to overestimate embodied carbon by approximately 68% compared to LCA. The study highlights that product weight plays a crucial role in the disparities between the two methodologies, especially in stages such as material acquisition, manufacturing, and end-of-life considerations.

Despite its overestimation, TM65 is considered a suitable starting point for companies assessing the environmental impact of their products due to its simplicity and adaptability. However, for more precision, a full LCA is recommended. The researchers emphasise that despite the overestimation, TM65 consistently follows the same trend as LCA results, making it a valid methodology for initial assessments.

Read the full study here.

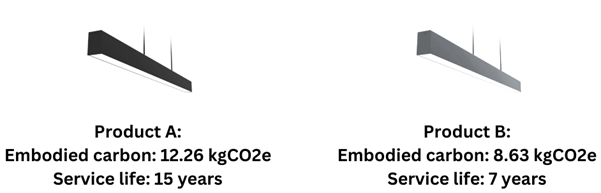

Here is an example of how TM65 can be used to quickly compare the embodied carbon of two different lighting products

Product A’s higher initial embodied carbon is offset by its extended service life, making it the environmentally preferable choice over Product B. Evaluating a product’s entire life cycle is crucial for informed sustainability decisions.

TM65.2

The latest iteration published in August 2023, TM65.2, introduces several enhancements, including improved accuracy and ease of use.

Key enhancements in TM65.2 include:

- More precise embodied carbon coefficients for various materials, ensuring more accurate carbon footprint estimations.

- A streamlined calculation process that simplifies application and reduces the risk of errors.

- Tailored guidance for lighting products, addressing their unique characteristics, and providing a more accurate assessment.

- Enhanced transparency and clarity of instructions and explanations, improving user-friendliness.

- An updated material database reflecting the latest material compositions and ensuring accuracy.

With these advancements, TM65.2 establishes itself as a more refined and effective tool for calculating embodied carbon in building services equipment. Further empowering construction professionals to make informed decisions that minimise the environmental impact of their projects.

How EGG Lighting is using TM65

You can find examples of how TM65 has been successfully used to report embodied carbon to customers in our remanufacturing case studies here.

By integrating TM65 into our remanufacturing process, we can accurately measure and report on the environmental benefits of remanufactured lighting products. This data clearly demonstrates the significant environmental advantages of remanufacturing over new product manufacturing.

We believe that TM65 is a valuable tool for lighting designers and engineers, allowing them to make informed decisions that prioritize sustainability when choosing lighting products for their projects.

If you have any questions about TM65 or the embodied carbon impact of our lighting products, please do not hesitate to contact us. We are always happy to provide additional information and support.